CORTEN LIFE SPAN INFORMATION

Read our content to know more about the life span of our products.

Corten Steel Care and Maintenance

Corten steel, is a high tensile steel that forms a protective layer of rust or patina when exposed to the elements. This patina shields the steel from further corrosion, giving it a characteristic reddish-brown color.

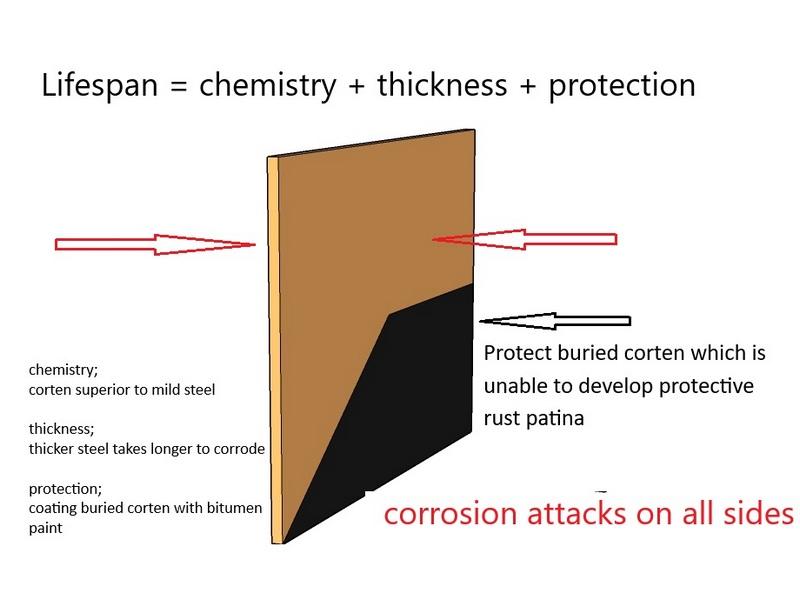

To form this protective patina, corten steel needs repeated cycles of wetting and drying. If buried or otherwise prevented from experiencing these cycles, corten steel will not develop the patina and will rust at a similar rate to mild steel.

To extend the lifespan of corten steel, ensure all retaining walls have adequate drainage to prevent hydrostatic pressure buildup. Poorly drained retaining walls with saturated soils will shorten the lifespan of unprotected corten steel.

For this reason, it is recommended sealing the insides of planters and the backs of retaining walls made of corten steel with a bitumen sealer.

Thin (1.0mm to 1.5mm thick) unprotected corten steel when buried has quite a short lifespan, and we do not sell thin corten for landscaping applications

By following these simple care and maintenance tips, you can ensure that your corten steel structures will last for many years to come.

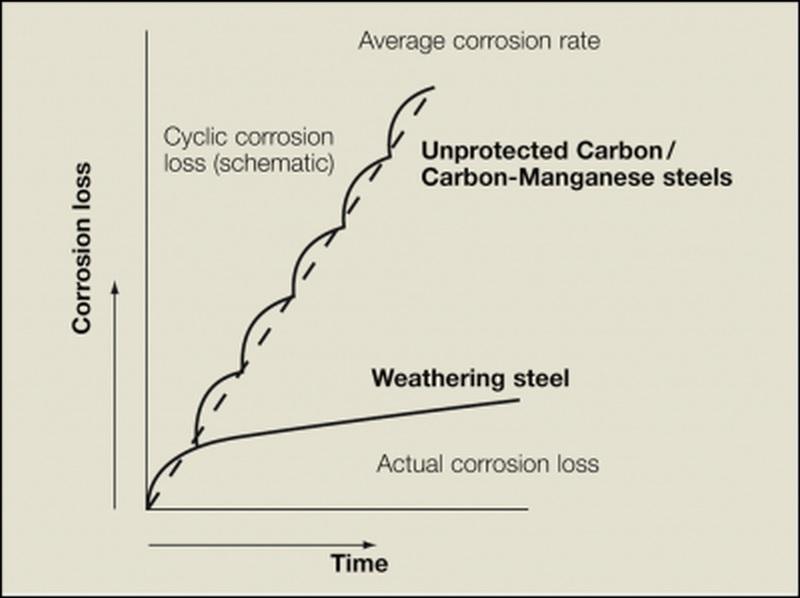

The weathering process is not linear, with approx 80% of the decay occurring in the first years of life, most specifiers therefore tend to use steel that is 0.5mm to 1.0mm thicker than required to allow for the expected corrosion.

Increased thickness = increased life span

Adding 1mm to the exposed face of corten steel adds approx 100yrs to life span

The life expectancy of weathering steel depends on the following

1/ the environment

2/ the steel is able to have repeated wet/dry cycles to form and maintain the protective oxide coating

3/ the thickness of the steel specified

Nominal loss of thickness for each 10yr period

Location | First 10yr period mm | Subsequent 10yrs mm |

|---|---|---|

Rural | 0.10 | 0.05 |

Urban* | 0.20 | 0.05 |

Industrial** | 0.20 | 0.10 |

* With the chief impurity in the air being sulphur dioxide

** In addition to sulphur dioxide the air also contains chlorine. Also for locations in the immediate vicinity of salt water

Corten steel slowly weathers over time

Image of pitted, blistering, flaky mild steel

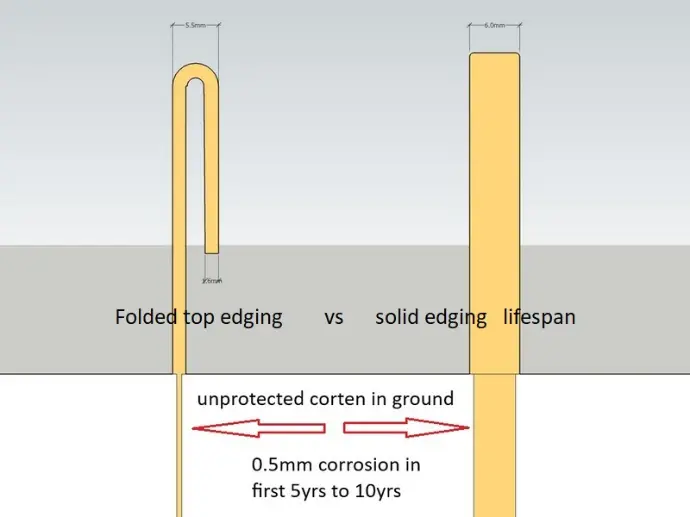

Thin folded top edging vs Solid edging

Suppliers of thin edging often fold the top over for the illusion of thickness, Cor-ten-steel edging is a solid 3mm or 6mm thick.

In 5ys to 10yrs time 1.6mm thick edging is likely to have corroded to the point of failure

Protect the backs of planters and retaining walls

The backs of the corten panels and support posts have been coated with bitumen, such as SikaTite BE Bitumen waterproofer or equivalent

Corten rust patina

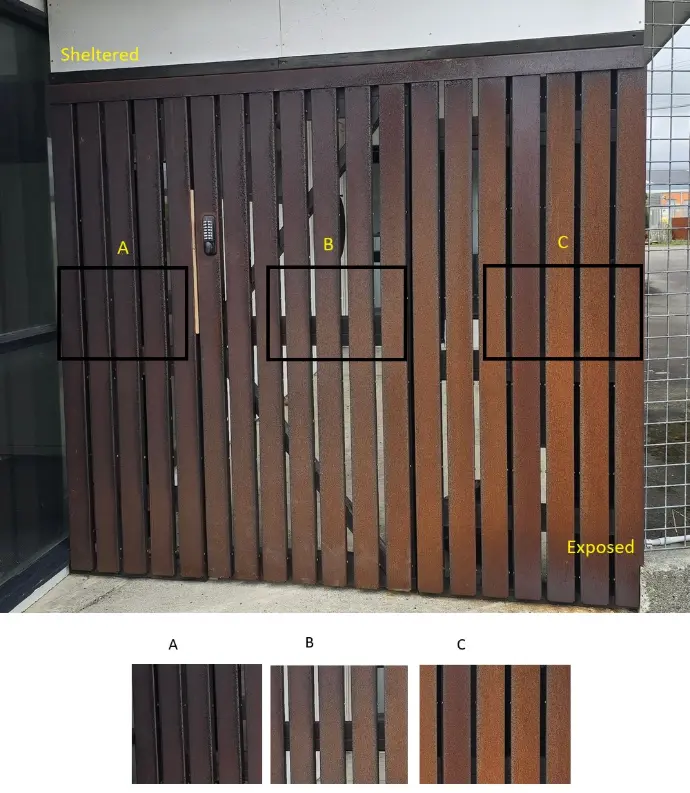

It takes repeated wet/dry cycles for the protective rust patina to develop. different wetting and drying rates will result in a some areas developing the patina a different rate to other areas.

The inherent nature of the rusting process, is that variations in colour, hue and texture should be expected, these variations are not considered flaws or defects

Cor-Ten steel is sold un-weathered (grey/blue steel) and will produce a rust run-off which will may stain stone, concrete, and decking surfaces. To limit staining to surrounding surfaces, designers incorporate gutters and gravel traps to direct the rust runoff away from surfaces, that could be stained

Example of shade variations due to different exposures to weather

Stainless Steel

Stainless Steel TEK screws or bolts should be used to fasten the corten weathering steel. Do not use zinc coated screws as this will result in bimetallic corrosion which occurs when dissimilar metals are in contact

The zinc anode will quickly corrode when an electrolyte (water) is present

Corten is not permitted to fix directly to galvanised steel, electrolytic isolation pads must be fitted to prevent any direct contact

Zinc flashings should not be in direct contact with corten, to avoid dissimilar metallic corrosion due to the large surface area of zinc in contact with the corten . A solution can be to install a non conductive permanent insulation layer between the two dissimilar metals

Stainless steel fixings

Corten Steel Properties

There is no warranty with unprotected raw steel, the specifier matches the expected environment conditions and the selected thickness of steel, to arrive at a prediction of the expected life span. Domestic landscaping applications may be happy with an expected life span of 30yrs plus, while bridge engineers often require 120yrs plus

Shipping container are made from corten steel, and are then painted to extend there economic life.

ASTM A606-4 or Q355NH commonly referred to as Corten,

Chemical composition(%)

C:≤0.16 Si≤0.5 Mn:0.5-1.5 P≤0.03 Cr:0.4-0.8 Cu:0.25-0.55

Mechanical property

Yield strength/Mpa:≥355

Tensile strength/Mpa:490-630

Elongation/%≥22

Lesser grades of steel, should not be referred to as corten, but can be called a weathering steel, we do not sell these lower grades, as the lifespan is less than ASTM A606-4 or Q355NH